No a smaller piston or a well used wasn't needed

To my knowledge the ceramic coating was just on the outside of the cyl not in the cyl boar

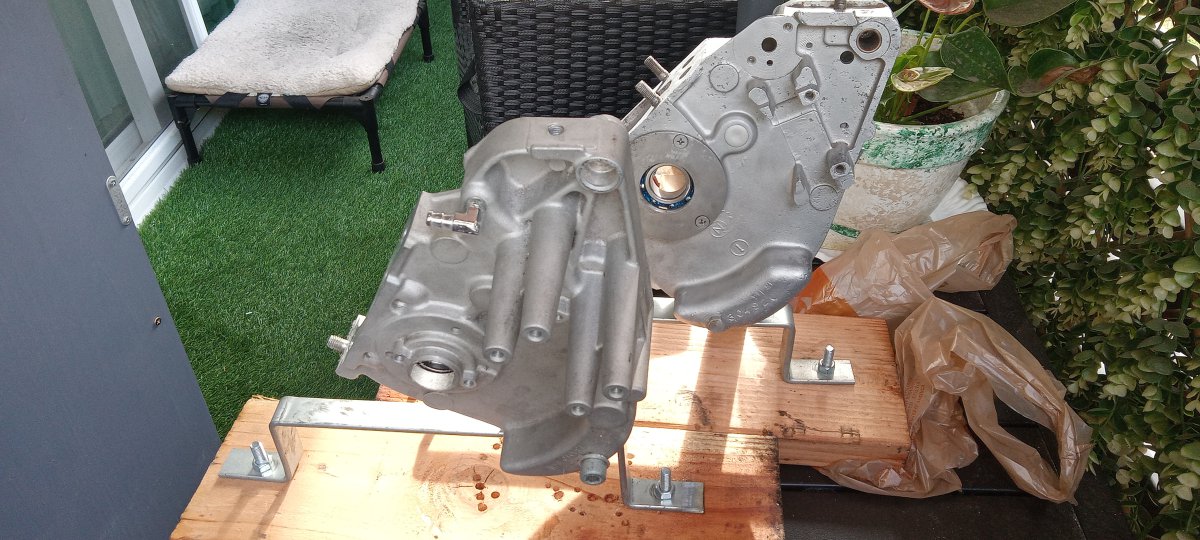

I ordered one of those ceramic (painted) cyls from, Paul I was just curious about the ceramic coating and the valve ports. I sent it back

Upon inspection of the cyl, The stock 57mm PREG piston ring end gap was too tight @ .006" should be a minimum .012" max .018"

If the engine was run with a piston ring end gap of .006" it will have a soft seize,

Thermal expansion and the rings end butt together causing a soft seize

Actually the cyl boar needed to be enlarged another .002" because for every .001' the cyl boar is made bigger the PREG will increase by .003"

3.14 x .002" = .00628" or .006" + .006" = .012"

Or the PREG could be filed to get the min- .012" but....

The cyl needed to be measured by a pro to check for proper PTCSWC piston to cylinder side wall clearance = .003" min .006"max

The cyl wasn't honed properly to fit the 57mm piston correctly

It could be easily fixed by honing out the cyl bore until the PREG measured .012" that means the PTCSWC

will be .003"

Fitting a piston should be done by a pro at a machine shop, I almost had the work done but I just decided to send it back

Because I use Westman cyls and got a few extra